Case study by Bitbloom

This case study looks at getting more from existing turbine operation data. Cubico Sustainable Investments is one of the world’s largest privately-owned renewable energy companies with a portfolio of more than 6 GW across 12 countries. The company, which is backed by the resources of Ontario Teachers’ Pension Plan and PSP Investments, has a keenly-felt responsibility to maximize the value and profitability of its assets. Bitbloom has worked with Cubico on its international wind portfolio for just over a year to help monitor and optimize operations, and has already identified yaw misalignment improvements and other opportunities to drive value and create significant cost savings. Crucially, Bitbloom’s technology was able to do so without costly additional hardware or upfront investment.

Demanding every drop of value from data

Cubico began working with Bitbloom in 2021, using Sift Monitor for asset monitoring across its wind-assets in the UK, Italy, Spain and Greece. In May 2022, this was expanded to include the United States, with Cubico’s first operational wind asset in the country: the 46.5-MW Wind Wall 1 project in California.

Wind Wall I. Credit

Cubico’s wind assets were operating smoothly; however, Cubico recognized the importance of keeping a close watch on operational data to detect and manage emerging risks, and to maximize energy generation – and therefore revenue – from every turbine.

A common drag on turbine performance is yaw misalignment. Turbines are most efficient when facing fully into the wind, yet wind flow is dynamic and complex while yaw systems for readjustment are inevitably slower. As such, dynamic yaw errors are ever-present and impossible to eliminate entirely. However, small discrepancies between the nacelle direction and wind direction have correspondingly small impacts on both loads and power. Instead, it is the larger, static, misalignments that inflict the significant energy losses as well as placing extra load on components. Here it is not a case of the nacelle playing catch-up to changing wind direction, but rather a constant offset that should be corrected.

A gold-plated approach to correcting static yaw misalignment is to invest heavily in an array of hardware and physical sensors, feeding into sophisticated analysis programs aimed at detecting even minute misalignment. However, this approach is arguably over-engineered and carries its own financial risk of failing to deliver sufficient return on investment to offset the initial outlay and ongoing operational and maintenance costs.

As a careful steward of its investors’ capital, Cubico wanted to explore all options and ensure value from its investments and found a likeminded partner in Bitbloom.

Bitbloom’s philosophy is to maximize the value extracted from the data that is already readily available before investing in solutions to gather more. Not only is this approach more cost-effective, it is often faster, and there is bountiful untapped value in data that has already been collected. Owners can then explore wider data collection and extend this analysis in future, but can do so in the knowledge that they have squeezed the most value out of what they already have before doing so.

The devil in the detail

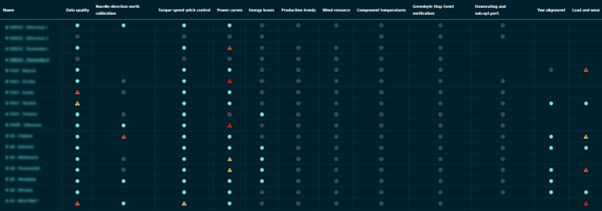

Bitbloom analyzed four years of Cubico’s historical 10-minute SCADA and event log data using automation on its Sift Monitor platform. After ingesting and quality assuring the data, Bitbloom would enrich the data before applying Sift Monitor’s performance monitoring algorithms. Run daily, these analyses were made available to both Bitbloom and Cubico via the Sift Monitor dashboard, which employs a simple traffic light system to draw attention to potential issues and alert on exceptions (Figure 1).

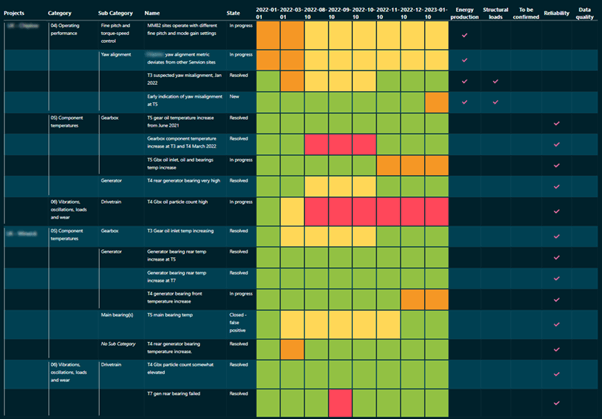

Bitbloom and Cubico meet regularly to discuss new issues and track progress on open items, using a task collaboration interface built into Sift Monitor (Figure 2). The interface is designed to both track tasks and collate relevant evidence such as analysis results.

In one of these calls, Cubico and Bitbloom had a particular agenda item to discuss: two separate algorithms had detected an anomaly, and a third had provided a true negative which, in combination, allowed the team to diagnose a yaw misalignment issue.

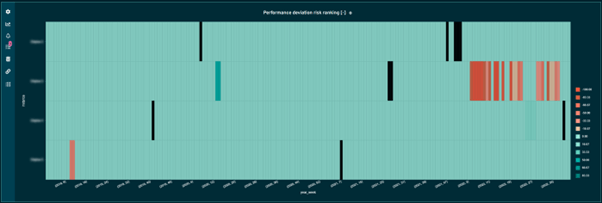

- Algorithm 1: A simple power curve and efficiency tracking tool indicating potential drop in efficiency (Figure 3).

- Algorithm 2: A wind speed consistency tool indicating no atypical increase in resource estimate for the specific turbine and period.

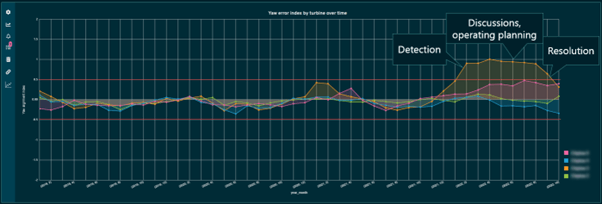

- Algorithm 3: A proprietary yaw misalignment algorithm indicating potential increase in static yaw misalignment (Figure 4).

In isolation, none of these indicators would have been sufficient to diagnose and resolve the issue; however, when combined, they pointed to yaw misalignment as the likely problem. Algorithm 3 specifically pointed to this, while algorithm 1 corroborated it with a drop in efficiency that algorithm 2 confirmed was not due to increase in wind resource.

For operators, it can be expensive to dispatch engineers to physically investigate issues, leading to a sensible reluctance to do so without strong evidence of a suspected issue. However, Cubico was able to present the operator with the evidence compiled by Bitbloom. The strength of this evidence persuaded the operator that a physical instrumentation inspection was justified.

Probing pernicious problems

Physical inspection confirmed what the data indicated: the operator discovered static yaw misalignment in excess of 10°.

With swift correction of the issue, the avoided energy loss alone was sufficient for Cubico to offset the cost of Bitbloom’s services for the entire European portfolio for an entire year. What’s more, as neither the operator nor service provider had the issue on their radar, it is feasible that it would have remained undetected for a long time, accumulating fatigue damage and component wear which, though difficult to quantify, could well account for greater avoided costs in repairs and downtime than the direct energy loss.

Today, Bitbloom continues to monitor various metrics for Cubico including yaw control and alignment, power controller operation, failure prognostics through temperature deviations and oil particle monitoring. By unearthing pernicious and expensive yaw misalignment issues, Bitbloom has validated its existing-data-first approach. Cubico was able to cost-effectively sweat its existing SCADA data to uncover the large misalignments that had the greatest potential to harm operations and profitability. In future, it may choose to invest in further data collection for analysis to optimize efficiency to an even greater degree, but it can do so knowing it has already made the bigger gains at a lower cost.

Filed Under: Featured