Flow measurement of high-pressure gas and liquid hydrogen

In the field of flow measurement, the use of hydrogen, especially regeneratively produced hydrogen, as a process gas and energy carrier has become a focal point in many applications. Due to the need to use storage capacity efficiently, hydrogen must be stored under high pressure or in liquid state. Metrologically verified quantity measurement is needed for the low to high pressure range of gaseous and liquefied hydrogen applications. In addition, appropriate traceability chains to the SI system need to be established for the wide range of operating conditions in order to make valid statements about the measurement accuracy and stability of the flow meters used. The EMPIR project 20IND11 MetHyInfra addresses these challenges by providing reliable data, metrological infrastructure, validated procedures and normative support.

Critical Flow Venturi Nozzles (CFVN) are widely used today and represent a standardised and accepted method of flow measurement. The main details of the shape and theoretical model are defined in the ISO 9300 standard. CFVNs are used in legal metrology and are recognised as a reliable standard with high long-term stability. The low cost and low maintenance CFVNs provide stable, reproducible measurements with a well-defined geometry and are only dependent on the gases used. The ISO 9300 standard describes two nozzle shapes, cylindrical and toroidal. In reality, however, the nozzle contours manufactured to this standard deviate from these ideal shapes. In most cases, the actual shape is between the two ideal shapes.

The achievable measurement uncertainty is also limited by the quality of the models of the thermophysical properties of the gases to be measured. The current reference Equation of State (EoS) for normal hydrogen (n-H2) was developed by Leachman et al [1]. Due to the limited thermodynamic measurement data available for n-H2 with comparatively high measurement uncertainties, the uncertainties for the various properties are generally an order of magnitude higher than for other gases.

Therefore, in this project, new Speed of Sound (SoS) measurements were performed at temperatures from 273 to 323 K and pressures up to 100 MPa. The data obtained were used to develop a new EoS for n-H2 optimised for gas-phase calculations [2]. The measurements made it possible to significantly reduce the uncertainties of the SoS calculated from the EoS in the investigated temperature and pressure range.

Extensive Computational Fluid Dynamics (CFD) simulations were carried out in the project to gain further insight into the flow physics in the nozzle. For this purpose, a numerical model for high-pressure hydrogen flows in the CFVN was developed in OpenFOAM, taking into account various relevant gas effects such as compressibility effects, boundary layer effects and transition effects. The results obtained are in much better agreement with the experimental data than previously available implementations.

In order to be able to evaluate and compare the flow behaviour of non-ideal nozzle contours, CFD simulations were also carried out for the ideal nozzles investigated experimentally in this project, as well as for parameterised nozzles. The flow coefficient of these non-ideal nozzles can be predicted very well using the proposed nozzle shape characterisation. The implementations developed in the project are freely available [3].

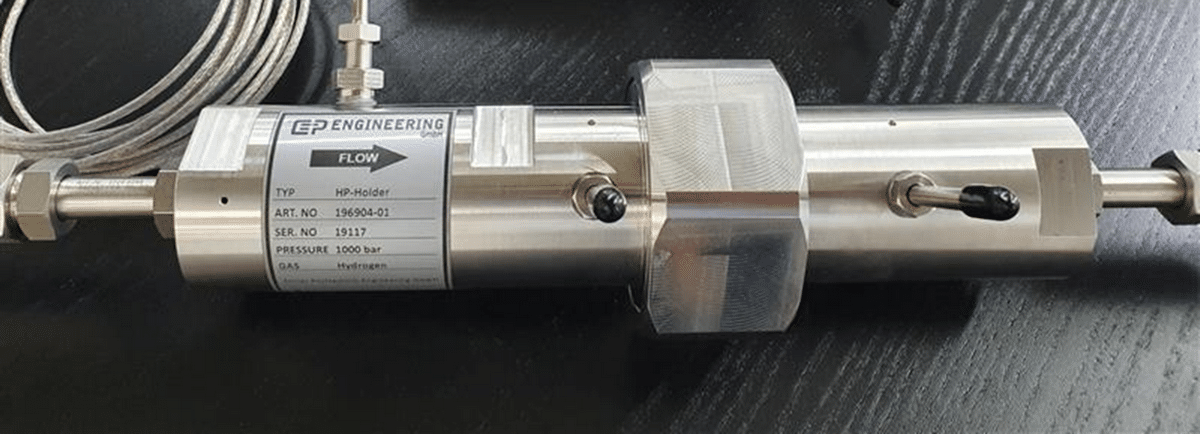

Figure 2: Mobile HRS flow standard

As there is currently no test facility with traceable standards available, that can be used to calibrate CFVNs directly with high pressure hydrogen, an alternative method had to be developed. The chosen approach is to calibrate a Coriolis flow meter (CFM) under high pressure conditions (range 10 MPa to 90 MPa) with a traceable gravimetric primary standard, so that it can later be used as a reference for the nozzle calibration.

The H2 test filling station (Hydrogen Refuelling Station, HRS) at the Centre for Fuel Cell Technology (ZBT) in Duisburg was selected for the calibration of the reference meter. For the measurements, a Rheonik RHM04 CFM was installed as a reference flow meter in the “warm zone” of the HRS, i.e. upstream of the heat exchanger and the pressure control valve. In this area, the temperature is always close to the ambient temperature and the pressure is constantly high, typically around 90 MPa. A mobile HRS primary flow standard was used for the calibration, which was connected directly to the HRS and thus took the role of a vehicle.

In the final step, the results of the CFVN measurement campaign will be compared with those of the CFD simulations. The newly developed EoS will be used in both the measurement campaign and the CFD simulations in order to compare both results in the best possible way.

Measurement method for liquid hydrogen

In addition to gaseous hydrogen, the project focuses on liquefied hydrogen (LH2). There are currently no primary or transfer standards for the measurement of LH2. The uncertainty associated with using a flow meter to measure the quantity of LH2 is unknown and unquantified as there is no direct traceability to calibrations using LH2 as the calibration liquid. The lack of calibration facilities means that meters used with LH2 must be calibrated with alternative liquids such as water, liquid nitrogen (LN2) or liquefied natural gas (LNG).

The project has therefore developed three approaches based on completely independent traceability chains for LH2 flow measurement. The first two approaches are applicable to flow rates during loading and unloading of LH2 tankers (flow rates up to 3,000 kg/h for a DN25 cross-section at pressures up to about 1 MPa), the third for smaller flow rates (4 kg/h for a DN3 cross-section at pressures up to about 0.2 MPa).

The first approach is based on the evaluation of the transferability of water and LNG calibrations to LH2 conditions. The study will identify and analyse potential uncertainty contributions for cryogenic CFMs. The experimental and theoretical analysis will serve as a basis for guidelines for the design and selection of CFMs suitable for SI traceable LH2 flow measurements. CFMs are a well-accepted technology for direct measurement of mass flow and density of liquids and are typically used in cryogenic custody transfer for transport fuel applications.

The literature review identified several temperature correction models applicable to LH2 flow measurement, i.e. how the LH2 flow measurement should be corrected due to temperature effects affecting the CFM measurement. Numerical finite element methods (FEM) for U-shaped, arc-shaped and straight pipe designs have been used to predict the temperature sensitivity of CFMs for LH2 flow measurement [4]. Finally, FEM can also be used to estimate the achievable measurement uncertainty using the current state of the art for LH2 flow measurement.

The second approach is based on cryogenic Laser Doppler Velocimetry (LDV) and is referred to as “Référence en Débitmétrie Cryogénique Laser” (RDCL). Traceability is ensured by velocity measurements and it can be used either as a primary standard or as a secondary standard for flow measurements of LH2. Its in-situ calibration uncertainty in cryogenic flows (i.e. LN2, LNG) has been estimated to be 0.6{c431b1036349617aea55b35aa92592c3cb3fecc7f94273a754a3b674e9a603ce} (k = 2) [5]. Since the RDCL can be installed in any LNG plant, it has the advantage that a representative calibration can be performed directly in the plant under process conditions.

Figure 3: LDV standard for traceable cryogenic flow measurement

The third approach is known as the vaporisation method. Traceability to SI units is ensured in the gas phase by calibrated Laminar Flow Elements (LFE) after the liquefied gas has been evaporated. The LFEs are traceable to the Physikalisch-Technische Bundesanstalt (PTB). As with the first approach, the transferability of alternative liquid calibrations using water, LN2 and liquefied helium (LHe) must be evaluated, as the calibration rig is not suitable for direct use of LH2 for safety reasons. The lower flow range and the fact that non-explosive gases are used are operational advantages of the evaporation method. Another benefit is the use of LHe (boiling point about 4 K) so that the uncertainty of the alternative liquid calibration is based on interpolation rather than extrapolation.

An important aspect to consider in the vaporisation method is the conversion of para hydrogen (para-H2) to normal hydrogen (n-H2), which has been studied in detail by Günz [6]. At low temperatures, para-H2 is present almost exclusively; at room temperature, the ratio changes to 25{c431b1036349617aea55b35aa92592c3cb3fecc7f94273a754a3b674e9a603ce} para-H2 and 75{c431b1036349617aea55b35aa92592c3cb3fecc7f94273a754a3b674e9a603ce} ortho-hydrogen (n-H2). Para-H2 and ortho-hydrogen differ significantly in certain physical properties such as thermal conductivity, heat capacity or SoS. These can strongly influence the gas flow measurement, depending on the measuring principle of the flow meter. LFEs used to measure gas flow at ambient conditions are not affected by this as density and viscosity show negligible differences, particularly in the temperature range of interest here.

In summary, the results of the project will increase the confidence of end users and consumers. The methods presented will ensure reliable measurement data, which is important for increasing the share of hydrogen in total energy consumption.

This project (20IND11 MetHyInfra) has received funding from the EMPIR programme co-financed by the Participating States and from the European Union’s Horizon 2020 research and innovation programme.

Literatur

[1] Leachman, J. W.; Jacobsen, R. T.; etc., Fundamental Equations of State for Parahydrogen, Normal Hydrogen, and Orthohydrogen, J. Phys. Chem. Ref. Data 38(3): 721-748 (2009) https://doi.org/10.1063/1.3160306

[2] Nguyen, T.-T.-G.; Wedler, C., etc., Experimental Speed-of-Sound Data and a Fundamental Equation of State for Normal Hydrogen Optimized for Flow Measurements. International Journal of Hydrogen Energy, 2024.

[3] Weiss, S. (2023). Derivation and validation of a reference data-based real gas model for hydrogen (V1.0) [Data set]. https://doi.org/10.5281/zenodo.10074998

[4] Schakel, M. D.; Gugole, F.; etc., Establish traceability for liquefied hydrogen flow measurements, FLOMEKO, Chongqing, 2022

[5] Maury, R., Strzelecki, A., etc., Cryogenic flow rate measurement with a laser Doppler velocimetry standard, Measurement Science and Technology, vol. 29, no. 3, p. 034009, 2018 https://doi.org/10.1088/1361-6501/aa9dd1

[6] Günz, C., Good practice guide to ensure complete conversion from para to normal hydrogen of vaporized liquified hydrogen, https://doi.org/10.7795/110.20221115

Authors: Oliver Büker, RISE Research Institutes of Sweden, Borås, Sweden, Benjamin Böckler, PTB Physikalisch-Technische Bundesanstalt, Braunschweig, Germany