High-Temperature Single Crystals Could Revolutionize Electric Vehicle Longevity

by Riko Seibo

Tokyo, Japan (SPX) Jul 15, 2024

A research team led by Professor Kyu-Young Park from the Graduate Institute of Ferrous and Eco Materials Technology and the Department of Materials Science and Engineering, alongside Kyoung Eun Lee, a PhD candidate, and alumna Yura Kim from the Graduate Institute of Ferrous and Eco Materials Technology at Pohang University of Science and Technology (POSTECH), has made a significant advancement in the synthesis of single-crystal cathode materials for electric vehicles. This breakthrough, achieved in collaboration with the POSCO Holdings N.EX.T Hub, was published in ACS Materials and Interfaces.

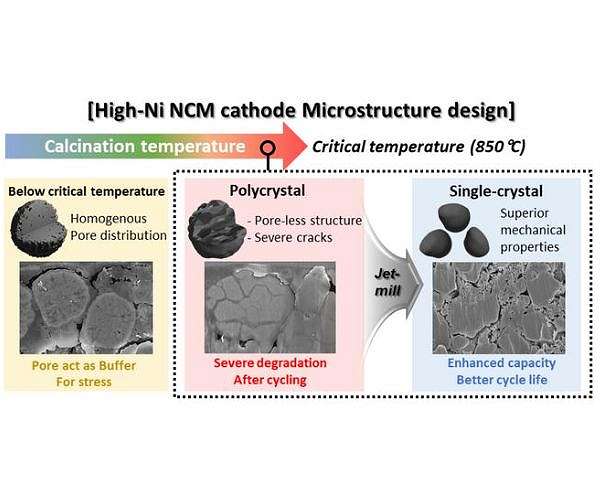

Lithium (Li) secondary batteries, prevalent in electric vehicles, function by converting electrical energy into chemical energy and vice versa through the movement of Li- ions between the cathode and anode. Nickel (Ni) cathode materials are commonly used for their high lithium-ion storage capacity. However, traditional nickel-based materials have a polycrystalline structure composed of numerous small crystals, which can degrade during charging and discharging, thus reducing their lifespan.

To overcome this limitation, the researchers developed a method to produce nickel-based cathode materials in a “single-crystal” form. These single crystals are synthesized as large particles, enhancing their structural and chemical stability and durability. While it is known that single-crystal materials are hardened at high temperatures, the specifics of this process and the conditions required were previously unclear.

The research team aimed to identify the “critical temperature” necessary for synthesizing high-quality single-crystal materials. They experimented with various temperatures to optimize the synthesis conditions for nickel-based cathode material (N884), observing the effects on capacity and long-term performance.

They found that polycrystalline materials synthesized below a certain temperature degrade more quickly in secondary batteries. However, when synthesized above this critical temperature, high-quality single crystals are formed, significantly enhancing durability. This improvement is attributed to a process called “densification,” where internal grain size increases and empty spaces within the material are densely filled, resulting in extremely hard and degradation-resistant single crystals.

Professor Kyu-Young Park explained, “We have introduced a new synthesis strategy to enhance the durability of nickel-based cathode materials.” He added, “We will continue our research to make secondary batteries for electric vehicles cheaper, faster, and longer-lasting.”

The study received support from POSCO Holdings and the Basic Research Program of the Ministry of Science and ICT.

Related Links

Pohang University of Science and Technology (POSTECH)

Powering The World in the 21st Century at Energy-Daily.com