Researchers from Ulm, Germany, have managed to develop a system that enables hydrogen to be produced from light energy, no matter the season or time of day. This photochemical entity could in future be used to provide hydrogen on demand to multiple applications – from sustainable heat generation to the refueling of hydrogen trucks and buses. Because the light can be stored, it allows hydrogen to be manufactured whenever it’s needed, and even in the dark.

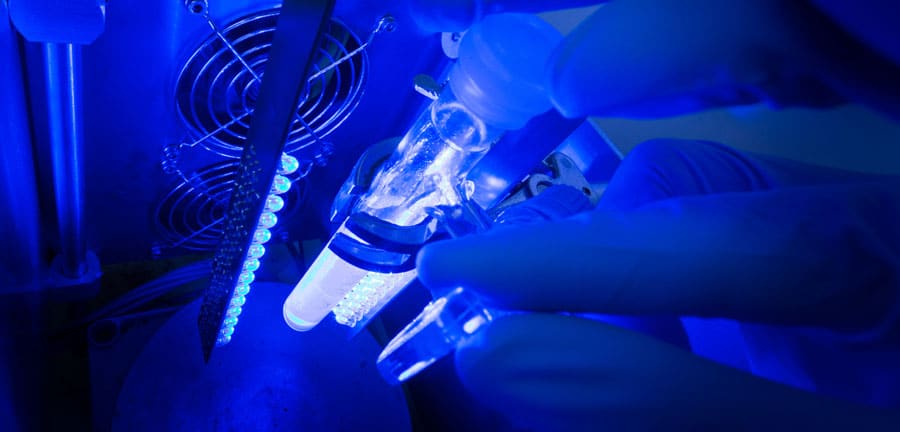

The new approach devised by the scientists in Baden-Württemberg is based on a unique molecule that can absorb sunlight, store energy and produce hydrogen. “In our molecule, light irradiation leads to charge separation and electron storage,” explains Professor Carsten Streb from the Institute of Inorganic Chemistry at Ulm University (see H2-international, April 2018). An easily storable fuel in liquid form is the result of the splitting reaction. The demand-responsive production of gaseous hydrogen is achieved through the addition of a proton source, says Streb.

The prospects for the new approach are very promising. Streb’s team has tested the performance of the system using a variety of analytical methods. Findings show that the molecular entity possesses excellent chemical and photochemical stability. The modular structure of the system allows for chemical changes and enables the overall system to be optimized. Hence the model could also serve as a blueprint for decentralized energy storage.

Mimicking photosynthesis in nature

Development of the photochemical system took place as part of a joint project. Researchers from Ulm and Jena universities modeled their ideas on natural photosynthesis and devised new materials for converting energy. One example is artificial chloroplasts for hydrogen production. The scientists have carried out a number of investigations, including important structural analyses that describe the reaction of the catalyst to light. This involved using an expensive piece of equipment for high-resolution mass spectrometry which was purchased with European Union funds under Thüringen’s regional innovation strategy.

Earlier systems designed to convert sunlight into chemical energy were relatively unstable. By embedding the light-driven catalyst molecules in soft matter, the consortium, which comprises chemists, physicists and materials scientists, has succeeded in stabilizing and controlling this process. The main aim of the now extended area of special research is to pave the way for the efficient decentralized production of green hydrogen.

Next: relinquishing rare materials

Rare materials like ruthenium, platinum or rhodium are still being used in catalysts. The goal is now to replace these costly, and sometimes environmentally questionable, components with more readily available alternatives. Organic dyes, for example, such as those being investigated in Jena, could be the solution to the problem. It is hoped that their instability will soon be resolved.

The plan is also to optimize the material link in the solar energy converters. “The aim is a light-driven process with linked oxidation and reduction. Added to that is the further development of physicochemical analysis methods,” explains Professor Benjamin Dietzek-Ivanši? from the University of Jena. He is the new spokesperson for the project now that it has entered its second funding phase. Meanwhile his colleague Carsten Streb has switched to the University of Mainz where he is continuing his work in this area.

The long-term goal remains the production of artificial chloroplasts. These are the parts of a plant cell that are responsible for photosynthesis. In future the consortium will also cooperate with the Center for Solar Energy and Hydrogen Research (ZSW) in Ulm.

More efficient than electrolysis

The demand for hydrogen is already high and is set to grow. At present, around 80 million metric tons of hydrogen are manufactured globally by means of steam reforming. The technique utilizes fossil fuels and therefore releases large quantities of carbon dioxide. In the near future, the emissions from hydrogen production will need to be eradicated or at least reduced through the use of low-emission methods.

Processes developed thus far for making green hydrogen often involve connecting up several components such as photovoltaic cells, batteries and electrolyzers. The disadvantage is that energy losses accumulate with every step, which is why hydrogen production is not very efficient. Despite the fact that the green electricity needed for electrolysis can be generated by wind, around 40 percent of the energy is lost during electrolytic processes. “The current targets for electrolytic production of hydrogen within the EU by 2050 will require 2,800 terawatt-hours. That is equivalent to the power from 250,000 to 460,000 new wind turbines,” calculates Professor Marko Huttula, who heads up a project examining the subject at the University of Oulu.

The advantage of solar hydrogen over electrolytic hydrogen is that it only needs the energy from the sun.

Finland: 7 percent efficiency in the lab

Photocatalytic processes have been the focus of study and research around the world for decades. The perpetual challenge is how to develop an efficient and long-lasting catalyst. This is because the catalysts usually degrade too quickly, or they require rare and expensive metals. In Finland, too, a new catalyst is being developed at the University of Oulu. In this instance it is composed of molybdenite – a relatively cheap, naturally occurring mineral. The compound structure consists of layered molybdenum disulfide together with nickel and silver nanoparticles which, according to the researchers, makes the catalyst relatively low in cost.

In the lab at the University of Oulu, in any case, the new catalyst was able to supply hydrogen for 86 consecutive days without decaying. During the trial, the catalyst reached an efficiency of 7 percent, which is above the threshold for useful efficiency of at least 5 percent. Alongside the production of hydrogen, the process also purifies the ordinary water used for hydrogen manufacture.

However, there is still a long way to go. “Many more years of research are needed before the production of solar hydrogen is possible on a larger scale,” admits Huttula. “The technology remains at a critical stage of development.”

Author: Niels Hendrik Petersen

Source: Eberhardt/Ulm University, Source: Heiko Grandel, Source: Eberhardt/Ulm University