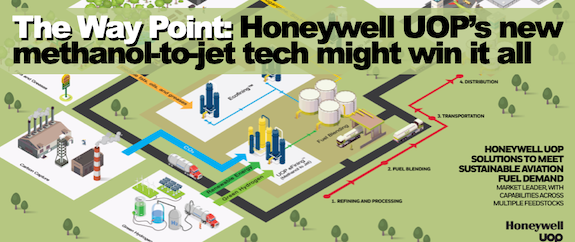

It may be that over the next few decades the most important feedstock for SAF will not be ethanol, or plant oils, but methanol. So it was big news last year when ExxonMobil announced a methanol-to-SAF technology, and even bigger news just now as Honeywell UOP announces a rival technology and a big customer with a tasty deployment timeline. Specifically, eFuels leader HIF Global intends to deploy the new technology to produce eSAF at its second U.S. eFuels facility.

The HIF eSAF project is expected to be the world’s largest eSAF facility, recycling approximately 2 million tons of captured CO2 to make approximately 11,000 barrels per day of eSAF by 2030, or just shy of 170 million gallons per year.

The boldest claim? An 88 percent reduction in GHGs, that’s based on CO2 ‘captured from biomass processing’ and green hydrogen.

Why methanol?

For observers in Digestville and elsewhere, if the question is “why methanol?” the answer is “The many effective ways to make it. Most well-known and long-proven. The many applications.” SAF is a new one, and we think the biggest of all.

How many ways to make methanol? One pathway is methanol synthesis, start with carbon dioxide and hydrogen, and with the reverse water gas shift reaction you can make carbon monoxide and water, then hydrogenate the carbon monoxide to methanol.

A second pathway is direct conversion of carbon dioxide and hydrogen to methanol — and CRI has been operating a plant in Iceland since 2012 with a 4000 ton per year (123 million gallons) plant since 2012.

There’s methanol made from methane. And those 38 percent methanol yields from destructive distillation of wood come to mind. There’s Enerkem’s MSW-to-methanol. What about methanol from gasified corn stalks?

The CO2 to methanol route is getting the most attention right now, of course. As the DOE’s Jay Fitzgerald put it, using the carbon we have to make the carbon we need. But look beyond the competitive edge of any single pathway. Look at the number of them. Out of diversity comes certainty.

Why methanol, now?

The problem with methanol has been the market for it which has been primarily in green chemistry, also known as The Land Without Carbon Prices. Green methanol has had to compete head-on with fossil methanol, and green methanol hasn’t exactly taken the world by storm.

It turns out that methanol is lot like an airport. You need it, but not so much as an end point as a way point. Connect the many roads to methanol with the many markets for SAF, you got something.

Green SAF made from CO2 is unlikely to be cheaper than fossil fuels, on an energy basis, but it’s all about the carbon intensity, now. The carbon credits, based on the kind of 88 percent reductions UOP refers to, will be large, and welcomed. And green methanol SAF is likely to be worth far than, say, green SAF made from corn ethanol, because the carbon intensity will be lower and the carbon value higher.

We might add, there’ll be excitement from environmentalists who see the potential to use waste CO2 as a feedstock and achieve low carbon intensity. From utilities and their partners intent on producing green hydrogen via water-splitting. Airlines who see the potential for more affordable fuels, and larger scales. And corn ethanol producers and their carbon-capture partners might raise a cheer, too, because corn ethanol plants and CO2 pipelines are an ideal place to pick up a large and pure stream of CO2. We do not have word where HIF, or others, will site methanol-to-jet facilities — we’d point right at locations close to abundant wind energy, water, ethanol production and a decent sized airport. That’s Big Ten country, and Iowa is going to be in the mix. With a slightly more challenging CO2 stream, think Gulf Coast.

So, exciting times.

Why SAF?

Yes, it’s the carbon targets. Everyone knows they are looming. Everyone knows that electric planes and hydrogen engines are technology built in the Way, Way Down The Line Machine.

So, the hunt for affordable SAF is like the Hunt for Red October, relentless, mysterious, tense, results measured in an awesome silence. The stakes are high because today’s SAF is like an Aston Martin, widely admired, seldom seen.

Meanwhile, governments have been falling all over each other to set gaudy targets with no affordable technology yet attached to them. 2021, the Biden Administration announced its Sustainable Aviation Fuel Grand Challenge for the U.S. aviation fuel supply sector to produce at least three billion gallons of SAF per year by 2030 and reduce emissions from aviation by 20{7bfcd0aebedba9ec56d5615176ab7cebc5409dfb82345290162ba6c44abf8bc8}, with an eventual goal of meeting 100{7bfcd0aebedba9ec56d5615176ab7cebc5409dfb82345290162ba6c44abf8bc8} of U.S. aviation fuel demand with SAF by 2050.

The Europeans are not to be outdone. They’ve released their ReFuelEU Aviation rules as part of the ‘Fit for 55’ package, which aim to increase the share of sustainable fuels at EU airports from a minimum of 2{7bfcd0aebedba9ec56d5615176ab7cebc5409dfb82345290162ba6c44abf8bc8} in 2025 to 70{7bfcd0aebedba9ec56d5615176ab7cebc5409dfb82345290162ba6c44abf8bc8} by 2050, with an additional subtarget for eSAF of 1.2{7bfcd0aebedba9ec56d5615176ab7cebc5409dfb82345290162ba6c44abf8bc8} by 2030 and 35{7bfcd0aebedba9ec56d5615176ab7cebc5409dfb82345290162ba6c44abf8bc8} in 2050. These and other incentives, including the Inflation Reduction Act, are intended to accelerate commercialization of technologies like Honeywell UOP eFining to help meet the growing demand for SAF.

Why UOP?

Three reasons, according to Honeywell UOP Renewable Fuels manager Leigh Abrams, a veteran of the ABLC stage who took some time this week with the Digest to explain the new tech, and it boils down to three things.

“It’s available today, it’s a very selective catalyst, and it’s based on existing and proven UOP technology,” Abrams told The Digest. In short, it’s got three of the four Musts that the winning SAF technology must have. It’s sustainable, available and reliable. The fourth Must is “affordable”, and it very well might be, the HIF Global contract speaks to that, we just don’t have anything to share from the UOP Fortress of Silence on that, at this time. We’ll snoop around.

The Bottom Line

Here in Digestville, we’re eternal optimists. After all, it’s just a little word scramble from “bongoes philistinism” to “Nothing is impossible” — and we have seen all too much bongoes philistinism when it comes to our management of emissions, and it’s high time for an era of ‘nothing is impossible’ remediation-by-technology. We sure like methanol, and anything that goes from methanol to SAF is adding about as much value as you can, given the carbon premiums. Affordable hydrogen, available CO2? Now you got something.

We think it’s likely that this technology wave will take us far down the road toward decarbonization.

Reaction from the stakeholders

“As a leader in renewable fuel technology, Honeywell recognizes that creating technologies that use new feedstocks is vital to long-term decarbonization of the aviation sector,” said Lucian Boldea, president and CEO of Honeywell Performance Materials and Technologies. “The ability to use readily abundant CO2 to produce SAF is a transformational opportunity for this market. Adding UOP eFining to our existing Ecofining and ethanol to jet technologies, Honeywell now offers multiple routes to market to meet the rapidly growing demand for renewable fuels including SAF.”

“United strongly supports the development of new technologies that can help bring additional quantities of SAF to market,” said United Airlines Ventures President Michael Leskinen. “Using green H2 and CO2 to produce eSAF has the potential to dramatically increase the volume of SAF required to enable the aviation industry to reach its decarbonization goals in a timelier manner. United is proud to be the first airline to use SAF in regular operations and increasing our SAF consumption is essential to meeting our commitment to reach net-zero carbon emissions by 2050, without relying on traditional carbon offsets.”

Renato Pereira, CEO of HIF USA added, “Honeywell and HIF Global together will transform recycled CO2 into a useful feedstock to replace fossil fuels in the very hard to abate aviation sector. At HIF Global, we view Honeywell’s UOP eFining technology as the new frontier in sustainable aviation fuels and we look forward to deploying it to decarbonize over 12 billion air passenger miles per year.”