With an expansion of the electrolysis capacity to 10 GW, water demand in German would barely rise. In consideration of climate change, however, the German association for gas and water standards (Deutscher Verein des Gas- und Wasserfaches, DVGW) advises implementation of an integrated system of water management.

This declaration by DVGW expert Dr. Florencia Saravia is straightforward and logical: “No green hydrogen without water.” The Deutscher Verein des Gas- und Wasserfaches e.V. has investigated what amount of water will be required for the production of green hydrogen by electrolysis. The result is clear: The drinking water supply in Germany will not be affected by this. Even with an electrolysis capacity of 40 GW, total water demand in Germany would only increase by less than one percent.

The water demand has more than halved since 1991, to 20 billion m3 (5,300 billion US gal). The main user is the energy industry, with 44 percent of the withdrawal. It mainly requires cooling water. This, however, is not consumed but, for the most part, fed back into the water system to be recycled. Increasing is the demand of agriculture. For irrigation alone in 2019, nearly 450 million m3 of raw water was used. In comparison to this, the amount of water calculated by the DVGW required for the targeted electrolysis capacity of 10 GW by 2030, namely 9 million m3 freshwater, is highly manageable in relation.

Production of ultrapure water

For the production of green hydrogen, ultrapure water is required. Via various process steps – pre-treatment, make-up/desalination, polishing/post-treatment – the raw water must be brought to the appropriate purity. The aim is to achieve a water quality of type I or II, explained Saravia. Depending on the manufacturer and the type of electrolyzer, there may be different specifications and requirements of the ultrapure water.

As a rule of thumb: 10 kg ultrapure water yields one kilogram hydrogen. In addition to that, cooling water is required for the operation of the electrolyzer. To be considered is also the nature of the raw water. If seawater is used, the yield will be 40 to 50 percent; with other sources like groundwater, it can reach 75 to 80 percent. Left behind is the separated concentrated brine.

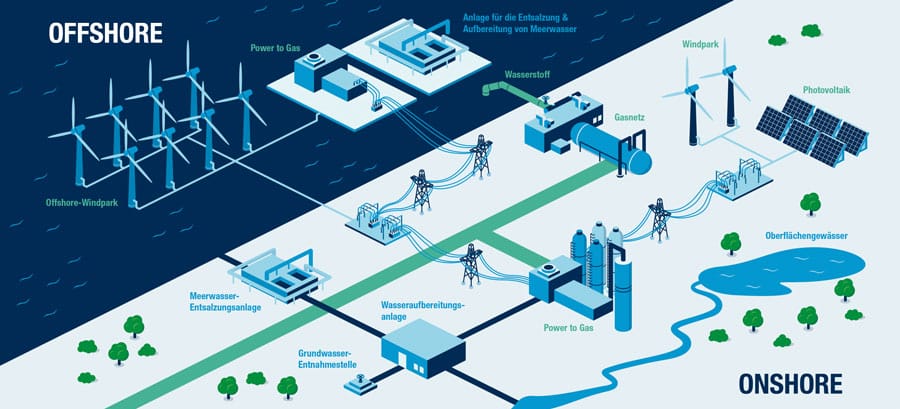

Which water sources will be tapped depends primarily on the location. If hydrogen is produced inland, purified wastewater can be considered in addition to surface and groundwater. Water already processed for drinking should not be used, according to the DVGW. Near the sea, desalinated seawater is also an option.

For offshore wind farms, two main options are available. If electrolysis takes place directly at sea, desalinated seawater is likely to be the material of choice. If, on the other hand, the electricity is first transported onto land and the hydrogen is produced there, the mentioned onshore options are instead available. According to a study by the foundation Stiftung Offshore-Windenergie that looks at the current plans, a third of the electrolysis capacities are to be installed offshore and the rest onshore.

Climate change factor

Despite the very small water requirement for electrolysis in context, climate change and its effects are becoming an increasingly important factor in the supplying of water. Here, the DVGW advises a supply strategy adapted for each location. Particular attention should be paid to regions that have been more severely affected by drought in recent years, like Brandenburg, Sachsen-Anhalt or Niedersachsen. Besides the use of seawater, Saravia advises in particular the use of effluent from wastewater treatment plants.

Here, policymakers should also get involved. Because the tapping of new water resources would also require new permitting laws, claims the DVGW. Clarified must also be how to handle the water discharged from electrolysis plants. For this, according to Saravia, several projects are currently underway.

Author: Michael Nallinger

Source: DVGW